Read time: 2 mins

Date posted: Apr 2024

Theme: Material Innovations, Sustainability

Lifecycle of Metal Powder

In the vibrant realm of modern engineering, the trajectory of metal powder embodies a captivating saga of metamorphosis, threading through a series of intricate stages including scrap collection, melting, atomization, quality evaluation, manufacturing, and ultimately, a sustainable reincarnation. This fascinating journey not only fuels industries like automotive, aerospace, and medical but also epitomizes the fusion of innovation and accountability within today's industrial world.

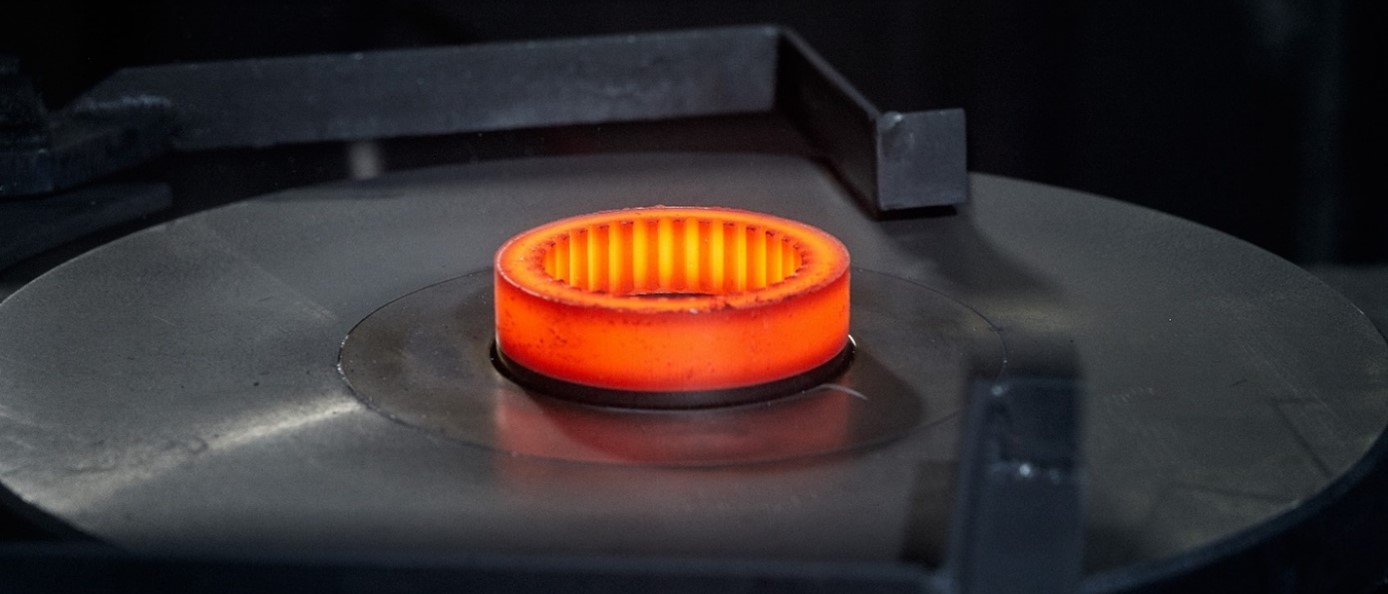

Melting

Within the crucible of advanced metallurgical processes, a diverse array of scrap metals is collected, each harboring latent potential awaiting realization. Meticulous melting procedures eradicate impurities from these metals, paving the way for a profound metamorphosis.

Atomization

Following the melting phase, the molten metal embarks on a journey of atomization. This intricate process entails the controlled expulsion of molten metal through specialized nozzles, where it encounters precisely directed streams of gas or water. The outcome manifests as the creation of metal particles spanning from 250µm to less than 25µm in size. Subsequently, water-atomized powder undergoes drying and annealing in a hydrogen-rich environment to eliminate surface oxides formed during atomization. This finely powdered metal emerges as the cornerstone of numerous industrial applications.

Check out our offering here: Metal Powder Portfolio

Rigorous Testing Standards

At this pivotal juncture, rigorous quality assessments are conducted on the metal powder. Thorough testing for critical attributes, including chemical composition, particle size distribution, apparent density, flow characteristics, and compressibility, is executed to ensure adherence to industry standards. Such meticulous quality control not only ensures the versatility of the metal powder but also guarantees compatibility with diverse manufacturing processes on the horizon.

Applications

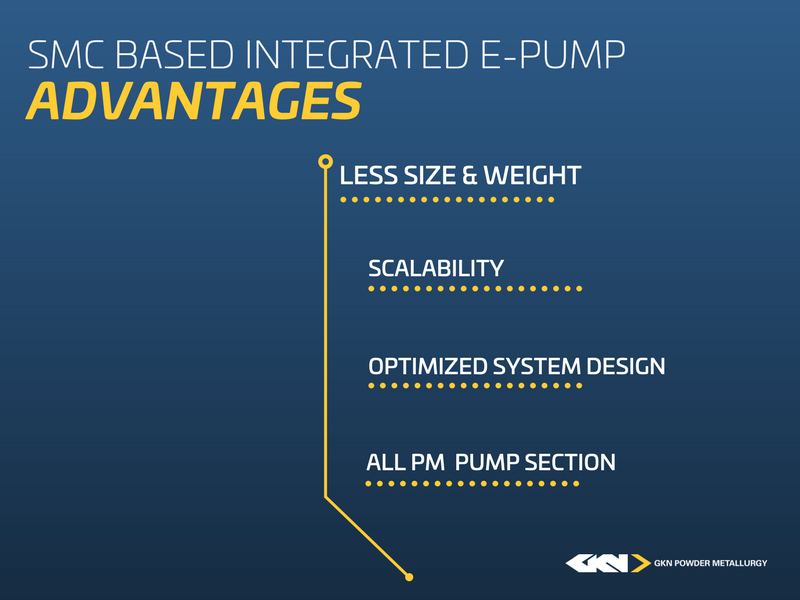

Endowed with certification and refinement, the metal powder now transitions into the manufacturing realm. Its innate versatility facilitates seamless integration into various production methodologies such as compaction, 3D printing, direct energy deposition, or injection molding. This finely powdered metal serves as the fundamental building block for essential components in automobiles, aircraft, medical devices, and numerous other applications, highlighting its versatility and importance across diverse industries. It has also made recent strides in the fields of magnetics and electrification.

Recycling & Sustainability

At the end of this lifecycle, the metal powder exemplifies the principles of sustainability. As the part nears the conclusion of its operational life, conscientious practices come into play. The metal powder is reclaimed and reintroduced into the crucible as metal scrap, thereby completing the cycle. This approach epitomizes the essence of the circular economy, mitigating waste generation and fostering environmental stewardship.

The lifecycle of metal powder is a technological marvel on its own; it constitutes a narrative of conscientious industrial practices, seamlessly melding innovation with a steadfast commitment to sustainability. As we navigate the intricacies of metallurgical processes, we chart a course towards a future characterized by efficiency, environmental consciousness, and boundless potential. The journey of metal powder serves as a guiding beacon, illuminating the path towards a harmonious coalescence of industry and ecology.

.jpg)