Read time: 3 mins

Date posted: Nov 2018

Theme: Innovation Culture

Creating the workplaces of tomorrow: Q&A with Paul Mairl

"We are on a journey of workplace transformation. Digitization is changing our working environments as much as our private lives and is offering huge benefits for companies and their employees. Industry 4.0 improves and facilitates business processes and working conditions, and it enables speed and flexibility.”

We spoke to Paul Mairl, Chief Digital Officer of GKN Powder Metallurgy, who believes Industry 4.0 and digital tools will assist in improved job performance without increasing workload; creating the workplaces of tomorrow.

Paul, you emphasize the importance of a business creating a digital culture. Does this relate to a specific mindset within GKN Powder Metallurgy?

Our company relies on engaged people who enjoy working in a team and finding their career aspirations with us. We listen to them, develop them and try motivating them to tap into their full potential. This means we encourage open communication and networking and encourage trial and error.

We want our employees to make their own decisions instead of constant monitoring, and we continuously improve our working environment to become more creative and open.

How does Industry 4.0 create better working environments?

Turning the benefits of digitization and Industry 4.0 into an advantage means not only working harder but also working smarter. Industry 4.0 makes work more soulful and productive as it becomes easier and quicker without the need to work harder.

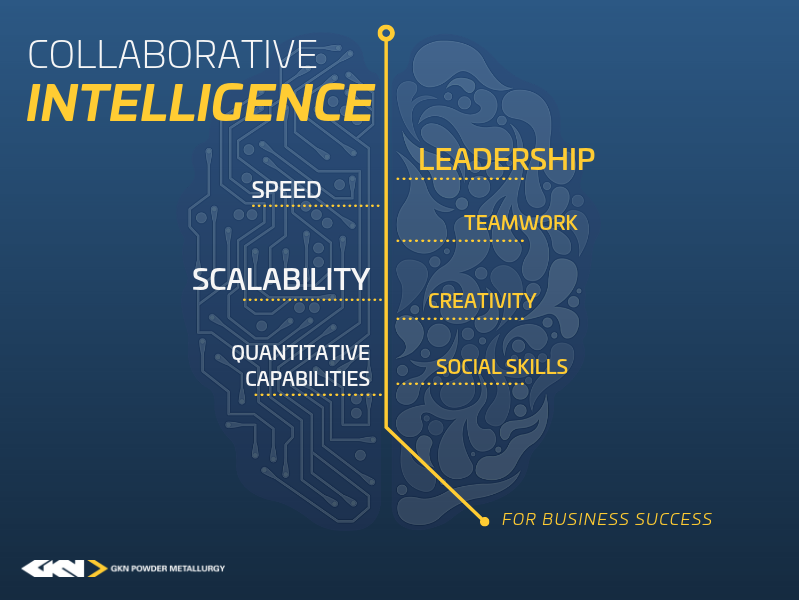

We achieve the most significant performance improvements when humans and machines work together. We call it collaborative intelligence: employees and Artificial Intelligence actively enhance each other’s complementary strengths. Humans ensure leadership, teamwork, creativity, and social skills. Machines provide speed, scalability, and quantitative capabilities. Business requires both types of capabilities.

Machines assist us in working smarter by providing real-time data, lifting heavy goods and completing jobs that would not be safe for employees. This now allows us to take on new duties, add greater value and focus less on repetitive tasks. Machines also support our personal development through improved trainings (e.g. by virtual reality) and allow us to learn just in time instead of just in case.

Digitization empowers seamless work-life-integration through flexible working models and remote working. Work-life-integration is one of our core values at GKN Powder Metallurgy, giving the opportunity to make free decisions about how, when and where we work. For many people, it is no longer a question of separating work and leisure time, but bringing them together comfortably.

Are employees at GKN Powder Metallurgy working smarter today?

Our digital journey at GKN Powder Metallurgy already started some years ago and we always put a strong focus on it. We continuously improved our business processes in line with our digital mindset and we keep nurturing our digital culture.

Today, our connected systems give us the real-time insight we need to make faster and better decisions. We plan staff and machines with our virtual production planning tool and our Visual Shop Floor visualizes real time data for remote monitoring of our shop floors all over the world. In our daily production meetings, each plant team can monitor yesterday’s production outcomes, the current KPI status, machine down times, and many more for minimized reaction time just by going into the system. Additionally, our reporting looks the same all over the world, available in real-time directly out of the system.

We are continuously working on several Industry 4.0 projects to make our shop floor jobs easier. For example, we have implemented new technologies like augmented reality training and problem solving to support our workforce.

Another aspect is seamless communication and collaboration. Process digitization and the constant availability of real time data is an incredibly powerful lever to drive communication, working globally, and organizational networking.

We want to enable boundless teamwork across all levels, improve the ideation processes and offer transparency. The diversity of available ideas as well as easily accessible knowledge means better results with greater time savings. With the tools and systems that are implemented, we empower decision making at all levels and offer the ability to work from anywhere while staying connected through mobile devices.

What do you consider most important in your implementation process?

As a business, it is important to understand that Industry 4.0 is not just about providing digital tools and infrastructure. It is about system usage and data driven decision making. This means we use the available digital tools, work on data accuracy, trust the data and then act on it. Only these steps will foster your digital culture that is essential to your competitive advantage.

What is your vision for future workplaces?

Industry 4.0 will further transform our workplaces. Many of today’s shop floor activities will change and have a much higher level of automation whilst digitization will grow people´s responsibility for processes and tasks. Many jobs that had a clear physical production focus in the past will be complemented by documentation and office-related tasks in the future.

The workplace of the future will create a new landscape of people, technology and space. It will be more intelligent, more connected and more emphatic – putting each of us in the center of our working environment. Augmented intelligence will enable us to focus on what’s enjoyable, strategic and creative. Intelligent workplaces will react to our moods and needs, increasing our well-being and helping us to do more. Everything will feel intuitive and seamless. The workplace of the future will encourage us to be more productive and creative in our own way.

/Digital%20Systems%20Downtime%20Thumbnail.png)

.jpg)